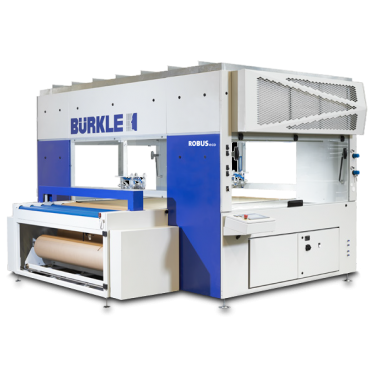

Weber Sander LCE 1350

Weber Sander LCE 1350

-

Brand:Weber

-

Product Code:Weber Sander LCE 1350

-

Availability:1

The LCE series is designed as a compact automatic cross sanding machine or simply as a wide belt sanding machine for use in skilled trades and for specific industrial applications. The entirety of WEBER sanding technology is available for perfect sanding results. The constant pass line enables effortless integration into production lines.

WEBER wide belt sanding for perfect sanding results:

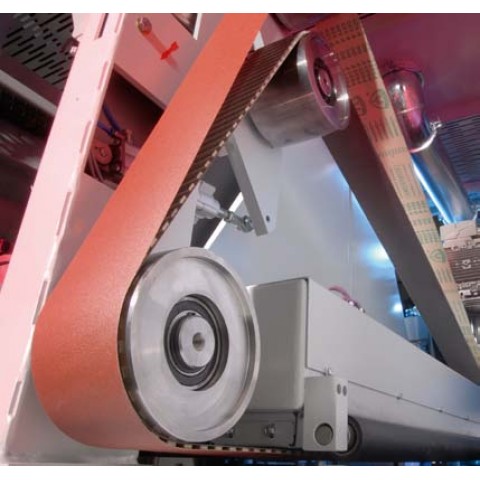

The contact roller is used in the production of plain surfaces, which is also known as calibration. The spiral-shaped, grooved roller guarantees the highest degree of precision and enables large chip removal and ensures a long service life as well. The sanding pad serves to ensure improved surface quality - with solid wood and veneers. The segmented version of the sanding pad with electronic control can process tolerances up to 2 mm with the highest consistent quality.

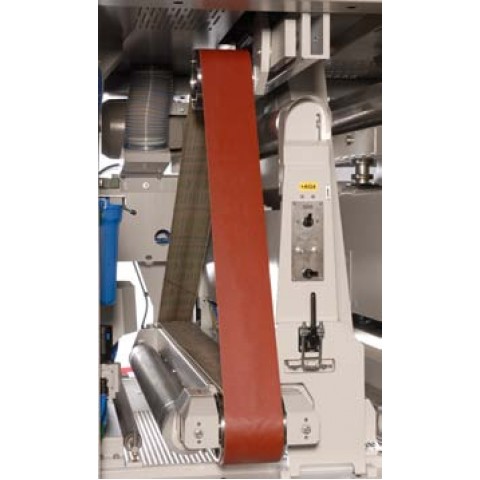

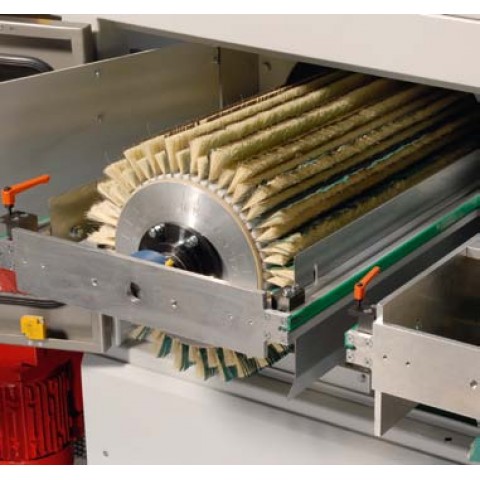

WEBER cross sanding for surfaces with reduced fibers:

Automatic cross sanding machines for the skilled trades have a long tradition at WEBER. Cross sanding means that the first sanding is performed crosswise to the feed direction and subsequent finish sanding in the lengthwise direction. The crisscrossing cutting motion offers advantages over multiple inclined or lengthwise sanding steps. The cross belt operates at a 90° angle perpendicular to the grain. As a result, the fibrous surface texture, which normally runs lengthwise, is divided into small sections and subsequent removal is simplified. This removal is subsequently carried out using one or more wide sanding belts. Due to the crisscrossing sanding directions, considerably fewer and shorter fibers remain on the surface.

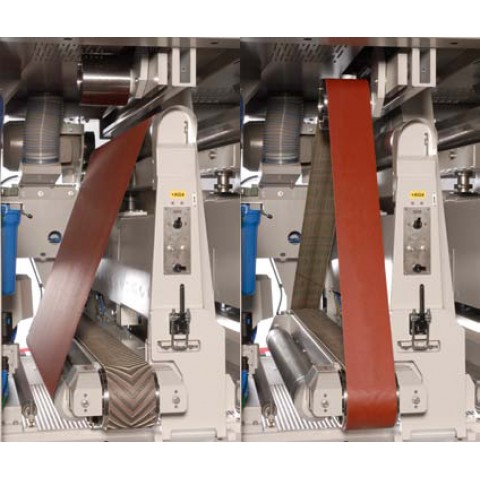

WEBER “X-Schliff” All sanding processes in one station:

Flexibility is becoming more and more important. For this reason, WEBER “X-Schliff“ offers all the sanding processes combined in a single station. The sanding station can be easily converted from wide belt to cross belt sanding. Thus, sanding processes can alternate between calibration, longitudinal, or cross sanding, or using WEBER CBF sanding technology. As today‘s requirements for various surfaces and lacquers call for different sequences of crosswise and lengthwise sanding, this new technology is able to respond to it. It enables lengthwise or crosswise final sanding, thus saving an additional machining station.

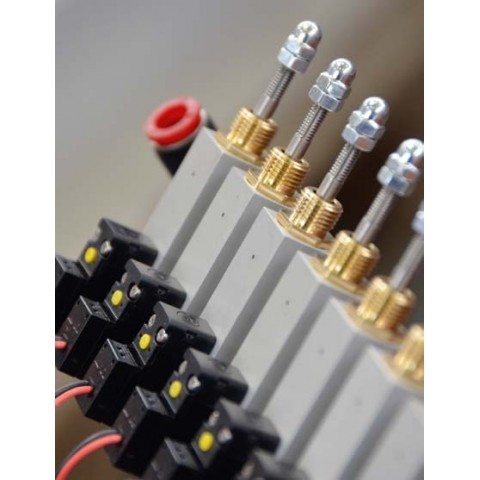

WEBER ISA/ISD segmented platen for perfectly sanded edges:

Uniform sanding pressure on edges and surfaces is a prerequisite for achieving good sanding results. The solution from WEBER: freely movable pressure pieces that are affixed to the sanding lamella always position themselves automatically flush against the sanding belt, the necessary uniform pressure distribution on lengthwise and crosswise edges then occurs automatically. This prevents the interference of lateral forces on the actuating cylinder. The arrangement of the pressure pieces on the sanding lamella makes every additional contamination-prone guide unnecessary, allowing the system to operate completely maintenance-free. In addition, certain areas can be processed with different sanding pressures: a great advantage, among others, during lacquer intermediate sanding, where lacquer material tends to build up along the edges in certain application procedures.

WEBER CBF Sanding Technology for smooth and even surfaces:

A sanded surface free from chatter marks is an outstanding quality feature. WEBER has found the perfect solution in CBF technology. It operates with a crosswise running lamella belt situated internally within the wide belt station. The pressure lamellas continually interrupt contact to the sanding grains and thus prevent the sanding belt from leaving undesired chatter marks. The result: the surface is perfectly smooth and even. At the same time, the continually changing force prevents the surface from heating up and the sanding belts from sticking during the processing of lacquered and plastic surfaces. Similar to a cross sanding unit, the lamella belt operates without a control system, it retains the full tolerance compensation of the sectional pressure beam, wears evenly, and is economical to replace.

WEBER planetary head for a uniform finish:

With the planetary head technology, WEBER is setting new standards in sanding quality. This patented head guarantees a perfect surface regardless of the direction of wood fiber or the shape of the workpiece whereby all edges are equally broken during the passage. It is also possible to process 3D – surfaces, radius and profiles. During the subsequent lacquering process the wood fibers practically do no more raise up which finally results in lacquer saving and better surface quality.

WEBER “i-Touch” and WEBER Matrix for intuitive operation:

A rotary knob known as the “i-Touch” makes navigating through the most important functions on the colored touch panel truly child‘s play. All sanding parameters such as e.g., sanding belt speed, feed speed, and workpiece thickness can be directly accessed and operated via the “i-Touch” controller. Only the information necessary for the current operation is displayed in the matrix representation. In addition to the main function, direct access to saved programs is also possible. The operator simply selects the desired type of processing. The machine adjusts itself completely at the single push of a button.

WEBER control system perfect sanding results at the push of a button:

The WEBER LCE automatic sanding machine comes standard equipped with a high-quality 8" touch operating terminal in color mode and is based on the Siemens S7 control system. The graphic operating terminal makes operation easy and efficient. All settings can be made and stored at the operating terminal. Integration in higher ranking control systems or interlinking with other machines is no problem.

- Simple operation due to graphic support

- 8" screen (optional 10.5")

- 300 program memory spaces

- External data backup (optional)

- Error diagnosis

- Remote maintenance