Elcon Vertical Panel Saw Advance

Elcon Vertical Panel Saw Advance

-

Brand:Elcon

-

Product Code:Elcon Vertical Panel Saw Advance

-

Availability:Pre-Order

The ADVANCE range makes cutting panels to size very easy, without the need for manipulation, turning, or stocking of strips in between horizontal and vertical cuts. Moreover, it offers the possibility to trim the bottom of (multiple) panels.

Advance clamping system for horizontal and vertical cutting to size in one course:

- Lifting of the panels for the bottom reference cut and for strip cutting from the bottom, allowing strips to be cut to size without taking them off the machine and bringing them back on for temporary stocking in between.

Automatic shifting back frame:

- To prevent damaging the support strip when cutting horizontally, the back frame is automatically lifted when the saw blade is at the height of one of the strips.

Clipboard for job cards:

- Handy holder of operator information or documents at the side of the control box.

- Cutting depth 80 mm

- Maximum thickness of the material: 80 mm

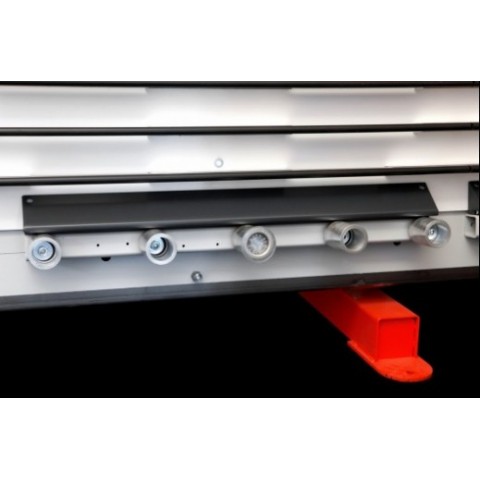

Double bearing bottom rollers, with pneumatic panel clamp and panel turn over possibility:

- For transport of heavy panels or a package of panels simultaneously, every meter-section 5 aluminum rollers are provided. A pneumatic clamp, that can be activated from the control panel, prevents that panels on the transport rollers move while cutting. In this way also light and thin panels can be cut accurately. In order to rotate bigger panels, the distance between 2 of the bottom rollers is chosen such that a panel can be turned very easily.

Entry and exit rollers for panel handling:

- Left- and right-side entry and exit rollers for easy panel handling.

Failure diagnosis:

- Location of possible failures by easy accessible LED display

For many different materials:

- Suitable for a wide range of materials, from wood-based to plastics, aluminum, and others.

Heavy, self-rigid carrying guidance modules:

- 600 x 100 mm rectangular steel casing for free-standing machine frame, with tension-free hardened steel bar guidance module for horizontal travel.

No special floor needed:

- Completely self-rigid and free-standing construction of the basic framework.

Pneumatic locking of saw-unit at working height, with fine adjustment:

- The setting of the measures for horizontal cutting, independent of the height of the position, is always at eye level, with micrometric adjustment for fine-tuning.

The pneumatic plunging of saw-unit:

- Easy movement of the saw-unit in and out of the panel, also when sawing in higher cutting positions.

- The precision within DIN 875/1 (0.1 mm.)

- Contact-free aligned hardened steel bar guidance for horizontal travel, from the precision template.

Programming rail for repetitive dimensions:

- Manual programming rail, for setting 5 different horizontal fixed measures.

- Standard equipped with 4 kW motor (s6)